In industrial piping systems, flanges may look like simple connecting components, but their quality plays a critical role in overall system performance. From oil and gas plants to power stations, chemical units, and water treatment facilities, flange failure can lead to serious safety hazards, costly shutdowns, and long-term financial losses. Understanding how flange quality affects safety, leakage prevention, and lifecycle costs helps businesses make smarter procurement decisions—especially when sourcing from reliable flanges manufacturers in India.

The Role of Flanges in Industrial Systems

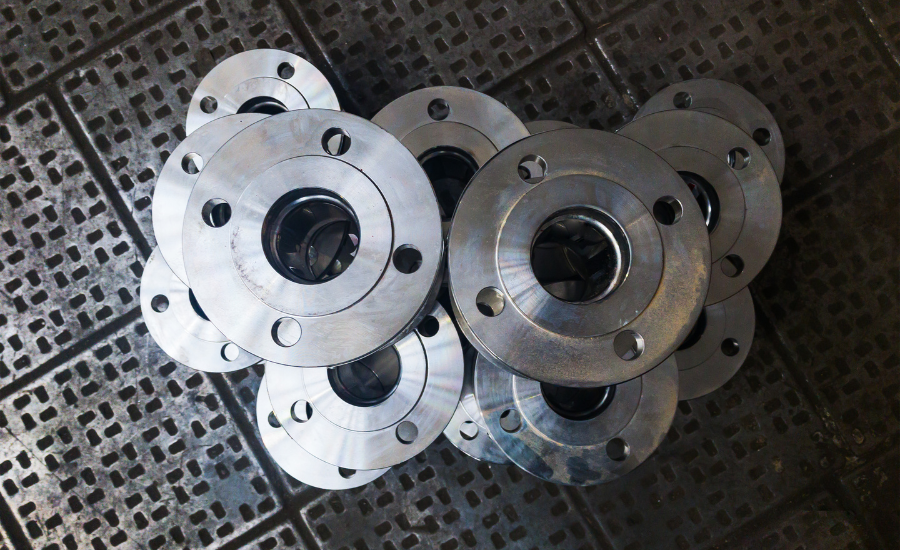

Flanges are used to connect pipes, valves, pumps, and other equipment, allowing easy assembly, inspection, and maintenance. Common types such as Slip on flanges and weld neck flanges are selected based on pressure ratings, temperature conditions, and application requirements.

While design selection is important, the actual quality of the flange—material composition, machining accuracy, welding integrity, and surface finish—ultimately determines how well it performs in real-world conditions.

Flange Quality and Safety: Why It’s Non-Negotiable

Low-quality flanges can compromise safety in ways that are not always immediately visible. Poor metallurgy, substandard forging, or improper heat treatment can weaken the flange under pressure or thermal stress.

High-quality weld neck flanges, for example, are designed to handle high-pressure and high-temperature environments. Their tapered hub ensures smooth stress distribution between the pipe and the flange. If manufacturing standards are not strictly followed, this stress-handling advantage is lost—raising the risk of cracks, deformation, or sudden failure.

In industries handling hazardous fluids, gases, or steam, flange failure can result in explosions, toxic leaks, or serious injuries. Investing in quality-tested flanges is not just a technical choice; it’s a critical safety decision.

Leakage Prevention Starts with Precision

One of the most common problems in piping systems is leakage at flange joints. Even minor leaks can escalate into major operational issues over time.

Leakage often occurs due to:

- Poor flange face finish

- Incorrect dimensional tolerances

- Uneven bolt load distribution

- Inferior raw materials

Slip on flanges, which are widely used in low-pressure applications, are especially sensitive to dimensional accuracy and welding quality. A poorly manufactured slip-on flange may not align properly with the pipe, leading to gasket failure and repeated tightening issues.

High-quality flanges, on the other hand, are precision-machined to ensure perfect alignment, proper gasket seating, and uniform bolt stress. This significantly reduces the chances of leakage, maintenance calls, and unplanned downtime.

Long-Term Costs: The Hidden Impact of Low-Quality Flanges

At first glance, cheaper flanges may appear to reduce procurement costs. However, the long-term expenses associated with low-quality components often far exceed the initial savings.

Hidden costs include:

- Frequent maintenance and replacements

- Production losses due to shutdowns

- Increased labor and inspection expenses

- Higher risk of environmental penalties

- Damage to connected equipment

High-quality flanges offer better corrosion resistance, longer service life, and consistent performance under operating conditions. Over time, this translates into lower total ownership costs and improved operational efficiency.

Reputed flanges manufacturers in India follow international standards such as ASME, ANSI, and ASTM, ensuring durability and compliance across global projects. This consistency helps industries maintain predictable maintenance schedules and budget control.

Material Quality and Manufacturing Standards Matter

Not all flanges are created equal—even if they look similar. Quality manufacturers focus on:

- Certified raw materials

- Controlled forging processes

- CNC machining for tight tolerances

- Non-destructive testing (NDT)

- Dimensional and pressure testing

For applications involving high pressure or cyclic loads, weld neck flanges manufactured with strict quality control provide superior reliability. Their strength and fatigue resistance make them ideal for critical pipelines where failure is not an option.

Choosing the Right Manufacturer Makes All the Difference

Selecting the right flange type is important, but choosing the right manufacturer is equally crucial. Trusted flanges manufacturers in India combine cost efficiency with global quality standards, making them a preferred choice for domestic and international projects.

A reliable manufacturer ensures:

- Consistent product quality

- Traceability and documentation

- Compliance with industry norms

- Technical support and customization options

Final Thoughts

Flange quality directly influences safety, leakage control, and long-term operational costs. What may seem like a small component can have a massive impact on system reliability and financial performance. Whether you’re using Slip on flanges for low-pressure systems or weld neck flanges for demanding industrial environments, investing in high-quality flanges from experienced manufacturers is a decision that pays off for years to come.

In industrial infrastructure, quality isn’t an expense—it’s protection, performance, and peace of mind.